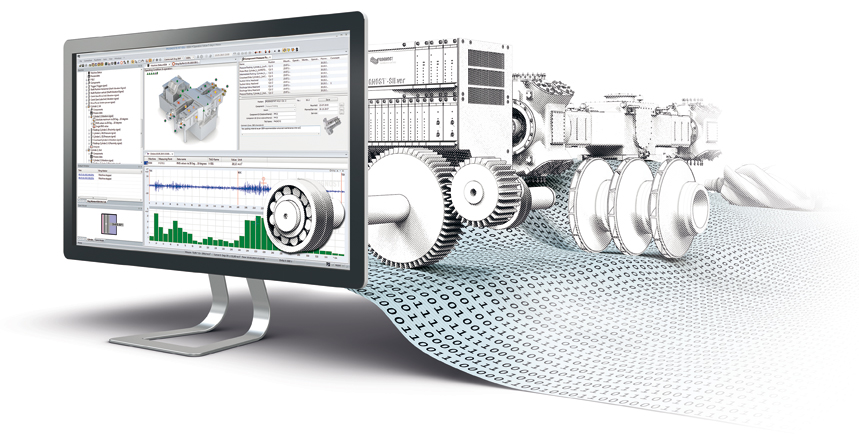

PROGNOST Products

Predictive Maintenance of Rotating Equipment with Online Condition Monitoring and Protection Technologies from PROGNOST Systems

PROGNOST Systems is the market leader for online diagnostic systems for reciprocating compressors and the inventor of the segmented vibration analyses. We offer specialized monitoring solutions and services for Rotating Equipment, including bearings, shafts, and gearboxes. This holistic portfolio allows our customers a successful implementation or expansion of the Predictive Maintenance approach.

Our products build upon 30 years of machine diagnostic experience and expertise in:

- Machine protection system (MPS)

- Machine monitoring system (MMS)

- Diagnoses of machine condition

PROGNOST®-SILver

PROGNOST®-SILver is a flexible, SIL 3 certified platform for integrated asset protection. It offers everything operators and instrumentation professionals call for.

This system is designed to provide machinery protection while maximizing production uptime. This hardware incorporates a smart modular concept that enables you to gradually replace or expand your existing system for additional protection tasks. It also allows users of previous PROGNOST®-SILver racks to re-use their existing PROGNOST® input cards.

PROGNOST®-NT

360° asset care of Rotating Equipment for Predictive Maintenance

PROGNOST®-NT is the perfect solution for condition monitoring on critical and uncritical Rotating Equipment. Machine operators who need to extend their MTBM (Meantime between Maintenance) by early failure detection rely on at least some of the PROGNOST®-NT software modules.

- SIL 3 Machine Protection (MMS)

- Modular Online Condition Monitoring (CMS)

- Automated asset diagnostics

- Intuitive graphical user interface

- 275 analyses and views for reciprocating equipment

- 188 analyses and views for centrifugal equipment

PROGNOST®-NT add-ons

PROGNOST® Cloud Dashboard answers your questions

PROGNOST®-Predictor

PROGNOST®-Predictor helps you to manage critical areas in your process. Whether your priority is to reduce off-quality production, increase efficiency, lengthen equipment life or reduce unscheduled downtime, this solution offers management tools and expert advice to help you to achieve your goals. Combining all of the PROGNOST®-Predictor capabilities results in optimal health of your machine and supports your Preventive Maintenance to Predictive Maintenance management.

Automated diagnostics for gearboxes and components

PROGNOST®-Predictor never sleeps. The system continuously monitors critical machinery, i.e gearboxes, warns of impending faults and allows Predictive Maintenance measures to be taken to avoid catastrophic failures. Specific analyses monitor multiple component types, including sleeve and rolling element bearings, gears, motors and shafts – providing health information and historical data.

PROGNOST®-SenSim

Device for the realistic simulation of sensors

The sensor simulation capabilities are:

- Simulation of sensors with separate setting for static and dynamic signal components

- Simulation of full sensor measuring range

- Predefined sensor library including most commonly used Eddy Current and Acceleration/Velocity sensor types

- Users conveniently apply values in units they regularly deal with (g’s, inch/sec, mil, bar etc). eliminating the need for complex electrical conversion into mV, mA etc.

- 2ooX voting logic

- The testing procedures can be carried out without taking off the sensors. This eliminates all associated risks, such as sensor damage or re calibration issues

PROGNOST®-NT Swift

Diagnostic support based on temporarily acquired PROGNOST® data

The mobile PROGNOST®-NT Swift system is the data acquisition solution when temporary online condition monitoring and diagnostic expertise are required. In combination with the Customer Support offering this powerful tool is the choice for initial start-ups of new compressors, temporary monitoring of machines with a failure history or production assets going back online after overhauls. These critical moments require offerings from short term temporary monitoring to repetitive periodical monitoring and finally long term monitoring.